Approach

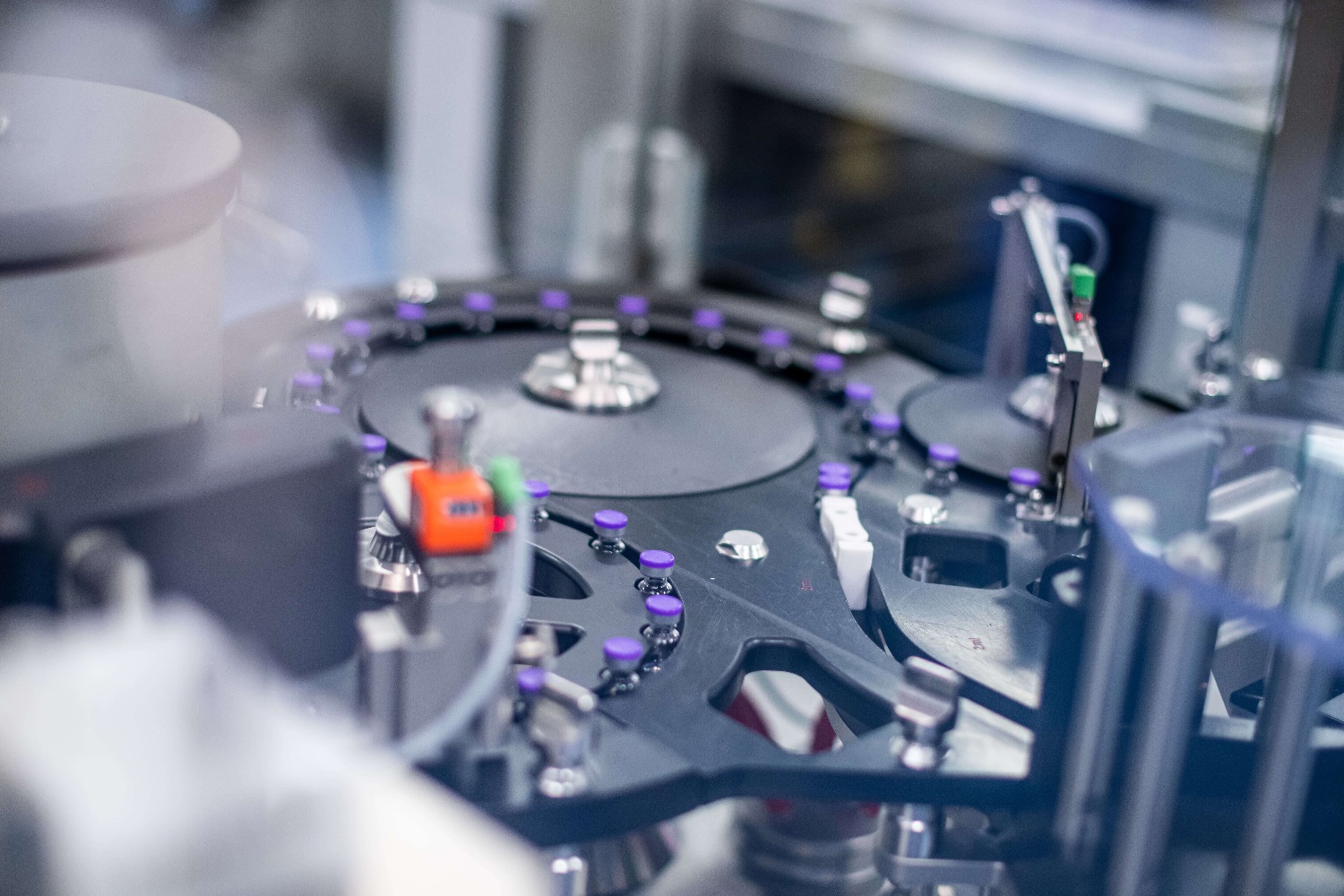

We began the project by immersing ourselves in the production environment, specifically focusing on the changeover process. Our approach involved a comprehensive understanding of the existing process through direct observation, interviews with operators and team leaders, and the collection of quantitative data. The combination of these methods ensured a holistic view of the challenges and opportunities for improvement.

-

Direct observation: We shadowed operators during changeovers, meticulously documenting each step and engaging in dialogue to gain insights into the nuances of the process.

-

Interviews: Conversations with both experienced and less experienced operators, as well as team leaders, provided a diverse perspective on issues, bottlenecks, and potential improvements.

-

Quantitative data collection: We utilised logging systems to analyse historical changeover durations and measured each step of the process, capturing valuable data on timing and potential obstacles.

-

Kaizen event: A collaborative Kaizen event brought together operators, team leads, and coordinators for a full-day session aimed at standardising the current changeover process, identifying pain points, and generating improvement proposals.

Following the Kaizen event, we had a detailed list of prioritised actions to enhance the changeover process. These actions were followed up during a weekly meeting with the project team to ensure progress and process change.

In the weeks that followed, Möbius collaborated with the support team, team leads, and operators to swiftly implement the identified improvements. These actions encompassed a range of strategies, including:

-

Operator training: Comprehensive training sessions were conducted, focusing on the conceptual understanding of each step, expected durations, necessary materials, and the option to indicate completed steps during the changeover itself dynamically.

-

System optimisation: The support team worked on enhancing the supporting system, allowing for parallel execution of process steps, addressing blocking factors, correcting errors, etc. After all, an operator can only change as fast as the system lets him.

-

Machine settings: Mechanical and software adjustments were made to ensure first-time-right runs, minimising the need for subsequent manual adjustments done by the operators.

-

Communication and visualisation: Improved communication strategies, information boards, and visual aids were introduced to streamline the changeover process.

This also included better visualisation of the targets themselves, so that operators could gain insight at all times into how on track they were for the production target, how smoothly changeovers went across shifts, and what potential problems occurred in the process.

Results

Thanks to the collaborative efforts of all employees, we achieved a remarkable 40% reduction in changeover time within just one month of implementing improvements. The continuous commitment to further enhancements aims to reach an impressive 60% reduction in changeover time, demonstrating the success of a comprehensive and collaborative approach to process optimisation in the pharmaceutical industry.