In today’s interconnected world, supply chain management has become increasingly complex. Companies are faced with numerous challenges, such as (de-)globalisation, volatile customer demands, increasing competition, and a need for greater efficiency. At Möbius, we help our clients to overcome these challenges by using supply chain analytics and modeling. In this blogpost, we will focus on supply chain network design and explore how analytics and data modeling can help businesses optimise their supply chain operations.

Supply chain network design is the process of determining the optimal physical network of factories, distribution centers, hubs, etc. in order to minimise costs while meeting customer demand. Strategic decisions have to be made about where to locate these facilities, how much inventory to hold, and in which locations to hold them.

Analytics and modeling can help companies to optimise their supply chain networks by providing insights into key areas

1. Facility location

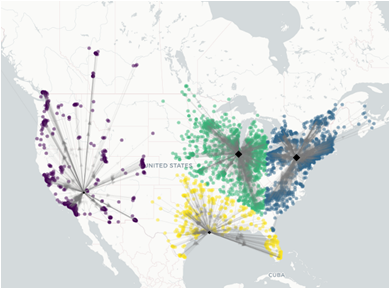

The facility location problem is a classic problem in operations research that aims to determine the optimal location of facilities, such as warehouses, distribution centers, and factories to minimise costs and maximise efficiency. A powerful technique we often use for this kind of problem is clustering. Customer locations are grouped based on their geographic location and demand patterns and provide a solid basis for determining candidate facility locations. Choosing these locations wisely can have a significant impact on the overall performance of supply chains and transportation networks.

2. Cost optimisation

Transportation cost optimisation is an essential part of logistics management. It can lead to significant cost savings and improved customer satisfaction, due to shorter delivery times and higher predictability. Different modeling techniques can be used to optimise transportation costs. The first step is to identify the objective of the optimisation: minimise total costs, maximise profits, or maximise customer satisfaction.

If the goal is to minimise overall costs, the candidate warehouse locations determined in the facility location problem can be used as a basis for the optimisation by minimising the overall transportation cost for all historic orders, given the candidate warehouse locations. In order to optimise overall costs, however, it is necessary to broaden our scope beyond transportation costs solely. We must include inventory costs to ensure we achieve an optimal balance between these two critical aspects of logistics management. By considering both transportation cost as well as inventory cost, the strategic network design will result in improved operational efficiency and increased profitability.

Mixed integer programming is an often-used tool commonly employed to address these complex logistical challenges. The outcome of the analysis includes a comprehensive plan that specifies which warehouse will cater to which customer and which products are to be served from each warehouse.

3. Inventory management

To calculate the customer service levels, inventory rules need to be defined and historic simulation can be applied to the outcome of the mixed integer programming model.

If the goal is to lower inventory levels as such, we can conduct intensive audits as in one of our projects where the goal was to boost service while reducing assets (cfr. case Air Liquide). We map and analyse the current planning system and set up an action plan to improve inventory accuracy, update calculation models for stock targets, and start rebalancing and lowering inventories, resulting in reducing inventory by 51%.

Read more about inventory analytics here.

4. Demand forecasting

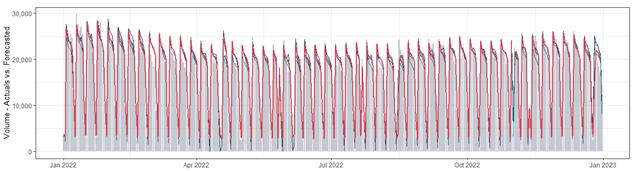

Demand forecasting models are used to predict future customer demand for products or services. Choosing the right forecasting model depends on the availability and quality of data, the level of accuracy required, and the time horizon of the forecast. The techniques we use can be divided into two categories:

-

Time series models: these statistical models use historical data to identify trends and seasonality patterns in demand. They are based on the assumption that future demand will be similar to past demand. A few of the models that are mostly used are ARIMA, Exponential Smoothing, and the Facebook-developed algorithm Prophet.

-

Causal models: causal models try to find variables, mostly economic indicators, demographic trends, and other external factors that influence the level of demand. Popular models include regression analysis and econometric models.

To get the best accuracy, we often combine different models in an ensemble technique such that the strength in each model is leveraged the most.

To get started on a good forecasting model, we collect the necessary sales data and apply the above-mentioned forecasting models. At this point, we disregard any knowledge of exogenous factors and base our results solely on historic data. The result is a model that forecasts volumes, taking into account the overall trend, and seasonality. In the next step, we carry out interviews with the stakeholders of the company to map any external factors that might influence the demand. We collect the data and implement the additional information in the existing model to forecast the errors, the volume not forecasted by the trend and seasonality.

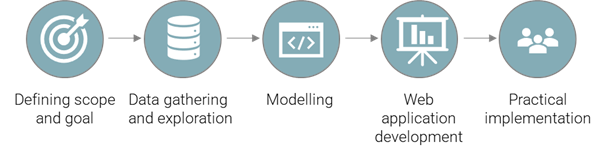

For many of these key areas within supply chain management, software is readily available to be used and implemented at the company. However, we often feel that these software packages are not always adapted to the specific needs of the company. The required data might not be available or businesses might be organised differently than is expected by the software packages. We like to work together with the client and customise our solutions based on their exact needs and necessary level of detail. Indeed, we highly value working shoulder-to-shoulder with our clients and supporting them in each step from gathering data to coming up with a solution and implementing the result in practice:

- As a first step, we identify together with the client the ultimate goal of the network design: lower inventory levels, shorter customer lead times, lower transportation costs, and so on. We explore the different potential model concepts we can use to translate their business problem into a mathematical one and identify the right optimisation goal.

- When the goal and concept are clearly described, we set up a plan for the data gathering and data exploration stage: what data do we need and at which level of detail? Is the data available and where can we find it? Do we see abnormalities in the data? We give a detailed exploratory analysis of the as-is situation.

-

In the third stage, we will start implementing the model concepts. We work through the different key areas one by one and only move to the next stage when the client approves the final model concept and results of the previous.

-

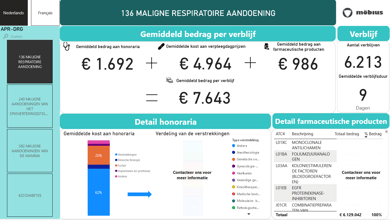

The final result of the complete network redesign is presented to the client, often in a web application. The advantage of building these custom-made web applications is that the client can rerun the model with different parameters or different date ranges to perform sensitivity analyses, without the need to have any programming and modeling knowledge. The application also allows them to see the result for different subsegments and separate clients or products.

-

As a final step, to bridge the gap between a model and the practical implications, we often help the client to put the theory into practice. The network design assumes that facilities can be located anywhere within a defined country or area, but does not take into account already existing facilities or locations where the construction of such a facility might not be possible. As a result, we set up a roadmap for the practical implementation of the network design.

Once the supply chain network is in place, we can also assist the client in testing the supply chain resilience of the new complete network. The world today has become much more uncertain and supply chains are subject to more risks, problems, and disturbances in the network compared to 5-10 years ago. Where we used to emphasise optimising networks based on a stable situation, we now notice that this starting point is no longer true at all times. Graph analytics and process mining can be used to test for weaknesses and bottlenecks in the network. We combine business knowledge with technical knowledge and work in iterations to increase the complexity of the model and work together with the stakeholders in each step of the process.

In conclusion, network optimisation is a critical aspect of supply chain management. It involves finding the most optimal physical facility setup such that overall costs are minimised and customer satisfaction is maximised. Together with the client, we will define the strategic goals and choose the model that suits the most. We will test the new network for its resiliency and bring all these aspects together in a resulting web application, ready for the client to use and to apply its scenarios and consult detailed views of the optimisation.

In this way, our clients can get a competitive advantage in this increasingly complex and interconnected world, where optimisation of the overall costs and improvement of operational efficiency is key.